Duct and Envelope Tightness (DET) Verifier Services

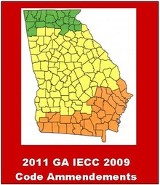

As of 1 Jan 2011, Georgia adopted the 2009 version of the International Energy Conservation Code (IECC 2009) with amendments. While most provisions of the energy code were mandatory immediately, some diagnostic testing and reporting provisions were delayed until 1 July 2011.

We can help with . . .

|

Home Insight is ready to test air leakage in your houses and ducts with a Blower Door and Duct Blaster. We also do heat load calculations according to ACCA Manual J and simple duct designs using ACCA Manual D.

Home InSight is a leader and leading provider of energy services to builders in the Southeast, particularly Georgia. Choosing a Certified Duct and Envelope Tightness (DET) Verifier is easy. They can all competently test.

|

When diagnostic tests pass, times are good. However, when they fail a HERS Rater, BPI Building Analyst, or a Home Performance with ENERGY STAR professional may be needed to help resolve provide effective solutions quickly. Without any of these other qualifications, a DET Verifier is only trained to run tests.

Air Infiltration Testing

We us a Blower Door for testing air infiltration through the building envelope. The goal is to determine whether air leaks through the exterior walls, floors, and ceilings limit natural air exchange to less than 1 whole-house air change every 3 hours.

The Georgia building code wants air leakage to limited to 7 air changes per hour at 50 Pascals (Pa): written as 7 ACH50. This is what is determined when the house is depressurized with a Blower Door at 50 Pa. This translates to 1 air change every 3 hours naturally, written as 0.35 ACHnat

Beware: When air exchange drops to less than 0.35 ACHnat, mechanical fresh-air ventilation becomes a consideration. We’re prepared to help design simple ventilation systems.

Duct Leakage Testing

We use a Duct Blaster to test duct leakage. The goals are to limit duct leakage to outside to 8% and total duct leakage to 12%.

Georgia does not require duct tightness testing when all the duct work is inside conditioned space. Directly and Indirectly conditioned spaces are included. Directly conditioned space is intentionally heated and cooled.

Indirectly Conditioned Space. Attics with foamed roof lines and unfinished basements without floor insulation above are examples of indirectly conditioned spaces. The definition of indirectly conditioned areas is murky.

Indirectly conditioned space is defined as “an enclosed space within a building that is not a heated space or a cooled space, containing un-insulated ducts, or containing the heating equipment or which is heated or cooled indirectly by being connected to adjacent space(s), provided that air from heated or cooled spaces is transferred (naturally or mechanically) into the space. Unvented Attic Assemblies meeting the requirements of the IRC are an approved indirectly conditioned space.”

In short, we'll need to help you figure it out!

Beware: We agree energy is not lost or gained when ducts are in directly conditioned space. The homeowner just won’t be getting all the expected air delivered to the room they wanted. Consider carefully whether to allow duct leakage to be excessive in indirectly conditioned spaces. They do have an effect on the size of heating & cooling equipment.

Common Duct Leakage Sites

Manual J Heat Load Calculation (aka Manual J Reports)

We use Wrightsoft’s Right J and Right Draw tools to model heating & cooling loads to produce Manual J reports. Two types of models are possible: block load and room-by-room. Both models depend on the building plans.

Block Load Model. Block loads are simpler and cheaper to build. If the house is similar on all sides in terms of surface exposure , windows, and doors, then a block load Manual J heat load calculation is reasonable. However, the cannot be used for duct design.

Room Load Model. Room-by-room loads take slightly longer and they produce results that can be used by installers to field design ductwork. When the building is irregular or has unbalanced windows and doors, including skylights, the room-by-room method is the way to go. If one heating & cooling system has several zones, room-by-room is the only way to go.

Room-by-room takes into account that different parts or the house will be exposed to the sun at different parts of the day. Getting the rooms right avoids callbacks do to hot or cold room complaints.

We can do either type of heating & cooling load with building plans. We do this for existing houses, so we’re prepared to go on site to gather the information too.

Beware: The ultimate responsibility for the accuracy of a Manual J report can only be the HVAC contractors. We provide the service and go over the results and methods we used to produce it the report. However, we can’t accept the liability for an improper load, especially when we don’t control the conditions or equipment the report represents.

We recommend not accepting any heat load calculation the HVAC contractor can’t support and defend. We’ll do the leg work, but the HVAC contractor has to take full responsibility for the result. We’ll make changes as needed throughout the project!

Manual S Equipment Selection

Once the Manual J heat load calculations are complete, equipment can be selected.

Evaluating Equipment Size. Home InSight does not choose equipment, but we do evaluate where the equipment is suitable by following ACCA Manual S, Equipment Sizing procedures.

HVAC contractors are experts in determining what equipment to use. Many are unfamiliar with knowing whether it’s the right size or not. It doesn’t help when the equipment distributors don’t know either. We have to make sure it’s right to do duct design. This service helps ensure the system is right-sized.

Beware: Many seasoned HVAC contractors fall into the trap of looking at the results of a Manual J heat load calculation to directly select equipment. The problem Manual J shows what the equipment has to provide.

The equipment itself has to have greater capacity because it has to be de-rated according to manufacturer’s performance data. Specs that work in Arizona on an 80 degree day will not in Georgia’s humid environment the last week in July and first two weeks of August. Delivered capacity can easily be up to a half ton or more less than advertised.

Manual D Duct Design

We design ductwork using Manual D Duct Design procedures using Wrightsoft’s Right D tool.

The building code requirement is to fabricate ductwork according to ACCA Manual D and other provisions of the building code. Other approved methods are allowed, which means designed by an engineering firm, usually by a mechanical engineer.

Home Insight is prepared to model un-zoned HVAC systems now. In the future, we’ll do zoned systems too. To do them, we need the HVAC contractors preferred duct layout and the chosen equipment, including air filter.

Beware: Believe or not, duct design is allowed without consideration for proper air distribution. Our duct designs include provisions from Manual T, Air Distribution. At a minimum, we help ensure the airflow to each room is just right (between 500-700 feet per minute (fpm)).

Energy Services Consultation (*#! Who are You Going to Call?)

Home InSight provides energy consultation services for new residential construction and existing houses. We are a Home Energy Rating System (HERS) Rater, Building Performance Institute (BPI) Building Analyst, Home Performance with ENERGY STAR Assessor, and EarthCraft House Technical Advisor. We we’re trained by Southface Energy Institute (SEI), the same organization training Duct and Envelope Tightness (DET) Verifiers.

We help builders of high performance houses in the EarthCraft program and ENERGY STAR Qualified Homes program build their houses to high green building standards. As such, we help with energy modeling, HVAC design, and insulation.

We help homeowners improve under-performing houses in terms of indoor air quality, moisture control, and energy efficiency. We use what we learn to help builder improve their construction practices.

We’re Building Code certified for all parts of residential construction. With the new energy code in place, we’re in a perfect position to help all home builders.

There is no way we can do all the diagnostic testing of new houses. Most will pass once everyone figures out how to meet the new diagnostic testing requirements. We can help get you started. More importantly, we can help when testing fails and it’s not obvious why.

|